Here is all the Stuff I printed with my new P1S thus far!

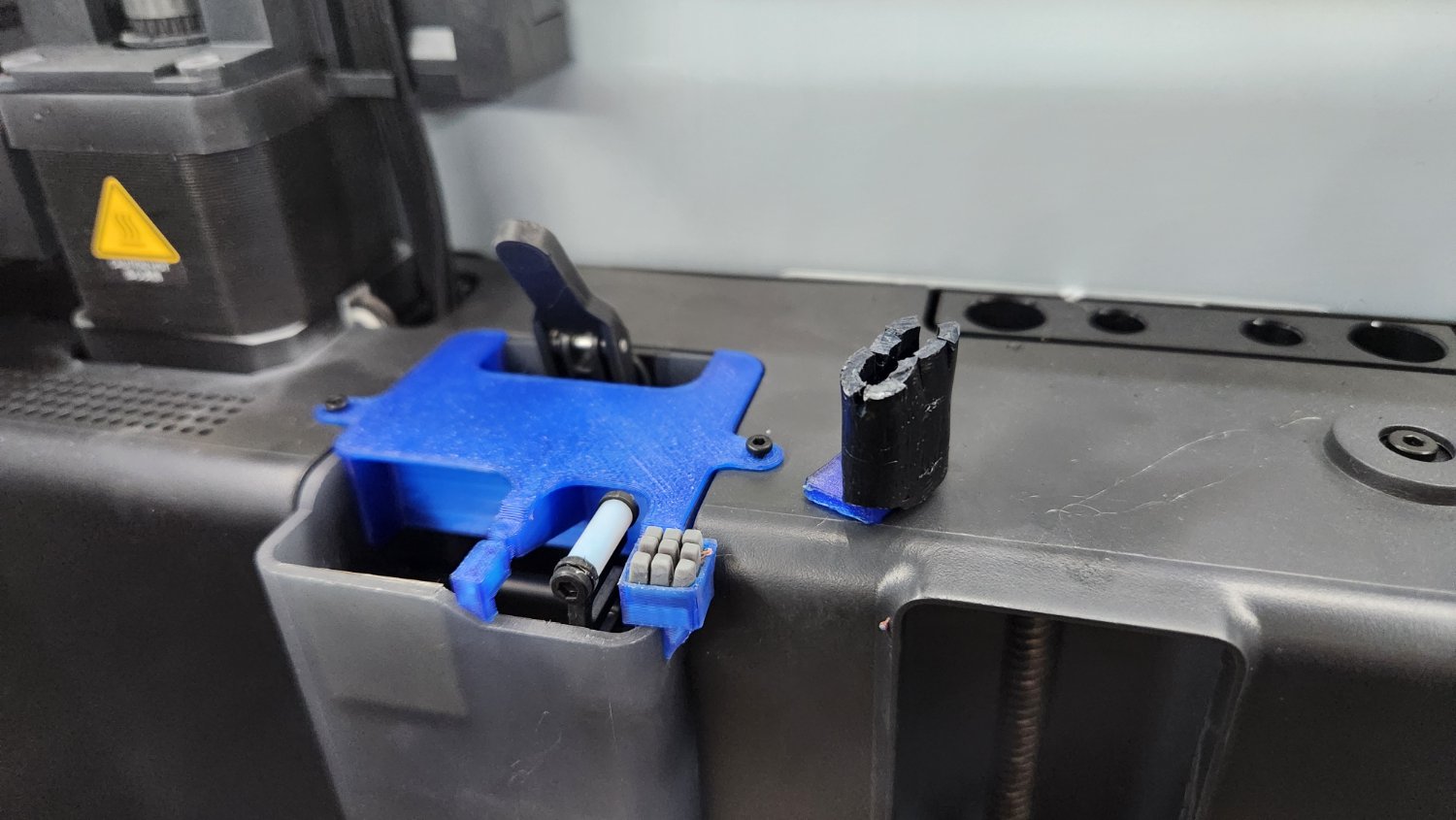

Since im here, I’ll need a bit of advice/guidance tho… For one, sometimes the nozzle doesn’t clean itself properly and flings its poop on the bed. From what I read I can put an A1 Nozzle Wiper somewhere to insure it cleans better?

And for the bigger, what I asume to be Issue, even when it wipes itself successfully, there always comes out a large string of Filament afterwards, which the P1S does not try to clean. Then going on to print away with this string still on. It seems very unintentional.

While this is manageable in single colour prints, it makes using the AMS basically impossible, as this happens after every Colour change. This is what the bed looked like after my only proper Multicolour Print…

Anyone faced the same issue who could maybe help me?

Hey see lots of people answering other questions but not the one you really want answered.

The basic nozzle wiper included sucks.

I have now tested probably about 4 different options and it’s something that you will want to replace soon if you are doing consistent filament swaps in a print. The A1 mini scrubbers don’t work quite as well as you would hope, mostly being that they hit the build plate back tab usually from where the nozzle wipes at and can grab filament and create a clog in the tube. I’m really liking the one I have on my printer though it needs to be printed with at least PETG realistically or ABS or ASA, but the nozzle wiper that uses a piece of tubing did the best job of cleaning the nozzle just also flung tiny little specs of plastic all over.

Buy more build plates also, especially textured as that will let you print everything basically and even TPU without a release agent on the build plate. I also really like the extra LED strip light replacement.

I’m currently in the finalizing my setup stages of an X1 and feel like I am finally in just printing away stage if you want to compare.

Maybe someone can answer this for me. Why do Bamboo Labs printers always have that stair step effect on the top-curves (top of the benchy)? The prints always look so good but my 10 year old Maker Select does better in that one spot.

I would assume mostly from trying to speed up print time.

The benchy is a 16 minute print and it lets the quality be good enough for that. If you are slicing the files yourself it can be a lot better especially if you are setting slightly lower layer heights and slower speeds.

Not all prints have it.

Have fun

Really getting tired of the Bambu Lab fan boys, there are already too many of us!

Hey there are other great printers but also it’s fine to recognize a great printer.

The rest of the industry is quickly playing catch up because the quality and the absolute bar lowering the printers from Bambu labs have done.

QIDI and the new Creality printers are already way better for it and we will hopefully and likely see more innovation from trying to dethrone them.

All to say I think the cheers are justified and worth it. And as soon as they are worth it I think people will stop.

Welcome!

To answer your question, what’s happening is that filament in the meltzone of the nozzle is melting and oozing out after the nozzle reaches temp. It will stop oozing once the tiny bit of filament in the meltzone melts and subsequently oozes out.

I am not a Bambu user, but if you can preheat the nozzle earlier relative to its wipe you should be golden. It looks like they don’t use Klipper, which means your slicer is probably controlling the order of things. Look at the print start gcode and have it heat the nozzle earlier. If you find whatever it has and copy/paste it here I, or someone else, will tell you what to move.

Happy printing!

I don’t have a Bambu but what they also need to look at is retraction settings after purging the extra filament.

Seems like it needs to retract a little more to lower the “pressure” of the melted filament in the nozzle.

Best analogy is that this is like a giant glue gun. Squeeze really hard and fast and the glue isn’t going to stop when you let up in the trigger. Except, with a printer, you can have the extruder “retract” a little which does introduce a vacuum effect and slow/stop the oozing.

Note: make small adjustments with a direct drive (which most of these printers are using these days) so you don’t pull molten plastic into the heatbreak and have to deal with clogs. However, if it’s oozing out you’re probably not even close to that being an issue.

I use Klipper and OrcaSlicer but when I get a new type of Filament (ABS, PLA, TPU) I tune it including retractions. This way it does cleaner lines and is less likely to leave blogs, stringing. And tuning filament retractions here (or something specific to purges) should fix the issue.

This is indeed the source of the extra filament. I’m just wary of suggesting you pull the filament too far up, which could take it out of the melt zone and cause a clog trying to get it back in.

If OP isn’t having stringing issues and wants to try this, they could add a smidge of retraction in the print end section of their slicer.

Exactly. Small (very small) adjustments.

Doesn’t Bambu Studio have some tuning menus? It may cover this.

I printed the poop chute too… but after the first time the poop backed up on a long multicolor print, I replaced it with a simple shoebox which holds a lot more.

We got the carbon x 1 at work and I like it a lot. It’s so easy to use.

I’ve fucked with 3D printers since my first undergrad in 2012 and Bambu p1s blows my mind every print. Never to this day have had a print failure or problems with bed adhesion

One of us! One of us! One of us!

I see you have chosen House Bambu, welcome! Be sure to print your AMS Pro upgrade, get yourself a bunch of Polymaker Dryboxes and a Dryer, and finally some Super Lube (and lithium grease).

What am I supposed to lube / grease? Just the Z screws or other stuff too?

Short answer: yes, please check the maintenance guides in the Bambu wiki and see the discussions on the Bambu forums.

Long answer: I gave some context replying to OP here. I hope this helps.

Oooooo what are some upgrades you’d recommend?

Ok so first of all, a disclaimer:

I’m not a 3D Printing veteran so please take my advice with a pinch of salt. My experience with 3D printers has been off and on over the last 10 years so whilst I’ve seen the hobby / industry change over time, I’ve only been hands on with a printer for a total of about 4 years, and only within the last 6 months have I had a printer of my own (Bambu P1S, and now an AMS for less than a month).

Those 2 of those 4 years were at university with a haunted and spiteful Makerbot Replicator my engineering department threw out, a tiny shitty cube printer with a disposable stick-down bed which was all the student Makerspace I helped set up could afford. The other 2 years was the brand new university FabLAB where I got my hands on an Ultimaker 2, my first love.

So whilst I have some knowledge I can share, it’s not that deep and I don’t want to pretend I know a lot about the specifics of Bambu printers when there’s very likely to be much more experienced people in this community. I’m still getting to grips with my own printer.

With that being said here’s some generic upgrades to consider:

This is the one is great because the measly Silica bags that come with the AMS are OK but this will vastly improve keeping your filament dry which is good because:

-

PLA when left out in average ambient air will absorb enough moisture to be unusable within 2 to 3 months and a lot sooner in a moist environment.

-

Moist filament, even if usable, will cause print artifacts and increased risk of print failure.

-

Some filaments like TPU absorb moisture a lot easier and therefore having a way to keep it dry passively in the AMS is good.

-

For this print, pick up a Hydrometer and some Silica Beads with this size bottle just enough to fill the containers.

Second, print the included bed scraper if you haven’t already. It’s the second thing I’d print after the Benchy.

Third, here’s some essentials to have on hand for maintenance:

-

Super Lube I use this for the metal bearing rods on the print head gantry and print bed. DO NOT APPLY to the carbon rods on the print head. It’s also super useful if you start hearing a rubbing / grinding sound whenever the bed jiggles during levelling / moving up and down OR the print head moving about. This is caused by the edges of the belt rubbing against the sides of the belt pulleys. I fixed this by CAREFULLY applying a very thin coat of the lube to the edges of the belts on the gantry and in the base underneath the printer. DO NOT GET LUBE ON THE BELT TEETH! I literally put a small dab of lube on my finger and running it carefully along the very edge of the belts.

[Don’t use this for cleaning the build plate, use warm soapy water] This is very useful for removing lube and grease when doing maintenance on your printer and I’d say it is the go to for cleaning those moving parts before re-applying lube / grease as appropriate. Speaking of which.

-

Lithium Grease. I used this on the z-build plate screw threads after the little sachets included with the printer ran out. After cleaning off the previous grease with the contact cleaner and a microfiber cloth I smeared a healthy dose of this along all 3 screw threads and moved the bed all the way up and down to get a nice even coat before wiping off the excess.

-

a BRASS wire brush. I’d recommend a brass wire brush for gently cleaning off gunk in your nozzle because brass is a softer metal than your steel nozzle so it won’t damage it, just be careful around the silicone sock.

And finally, you should get yourself an active filament dryer.

I personally use Polymaker’s PolyDry Dry Boxes and Dryer because I like that the drying base is detachable so once the filament has been dried it lives in the sealed box until I pop it out to put it in the AMS. Check for a local distributor but they can be found occasionally on Amazon but the cheapest place is AliExpress though you will have to wait for a while for them to arrive.

There are other solutions out there so I’d advise taking a look and doing some research by watching some reviews on the multiple brands out there at different price points so you get an understanding for yourself and what you think your needs will be.

Aside from that, the rest is up to you to figure out as you learn ☺️.

Want to print in more detail? Consider buying a 0.2mm nozzle. Want to print in carbon fibre or other abrasive filaments? Have a look at Diamond Back nozzles for Bambu made by E3D.

But what I would highly recommend, if you can, go to your next and nearest 3D Printing / Maker festival and enjoy some time chatting in person with others in the community.

Please let me know if you have any other questions and I’ll do my best to answer or try and point in the right direction.

Can’t recommend a filament dryer enough, this is a great tip. The AMS itself helps keep your filament more dry longer than being exposed to the elements, but you really should consider a good dryer.

As far as nozzles go, mind the filaments you plan to use with them, as a .2 nozzle is way more likely to clog with “filled” filaments, but if you’re printing non abrasive, non filled filaments and you want the extra detail you can’t beat a .2 - i purchased the CMYK lithophane kit and the detail with the smaller nozzle makes them almost photo quality. The great part is, though, bambu nozzles are far simpler to change than most other printers. If you plan on swapping them often, I’d recommend printing the cable/connector removal tools as the connectors can be a bit fiddly.

-

-