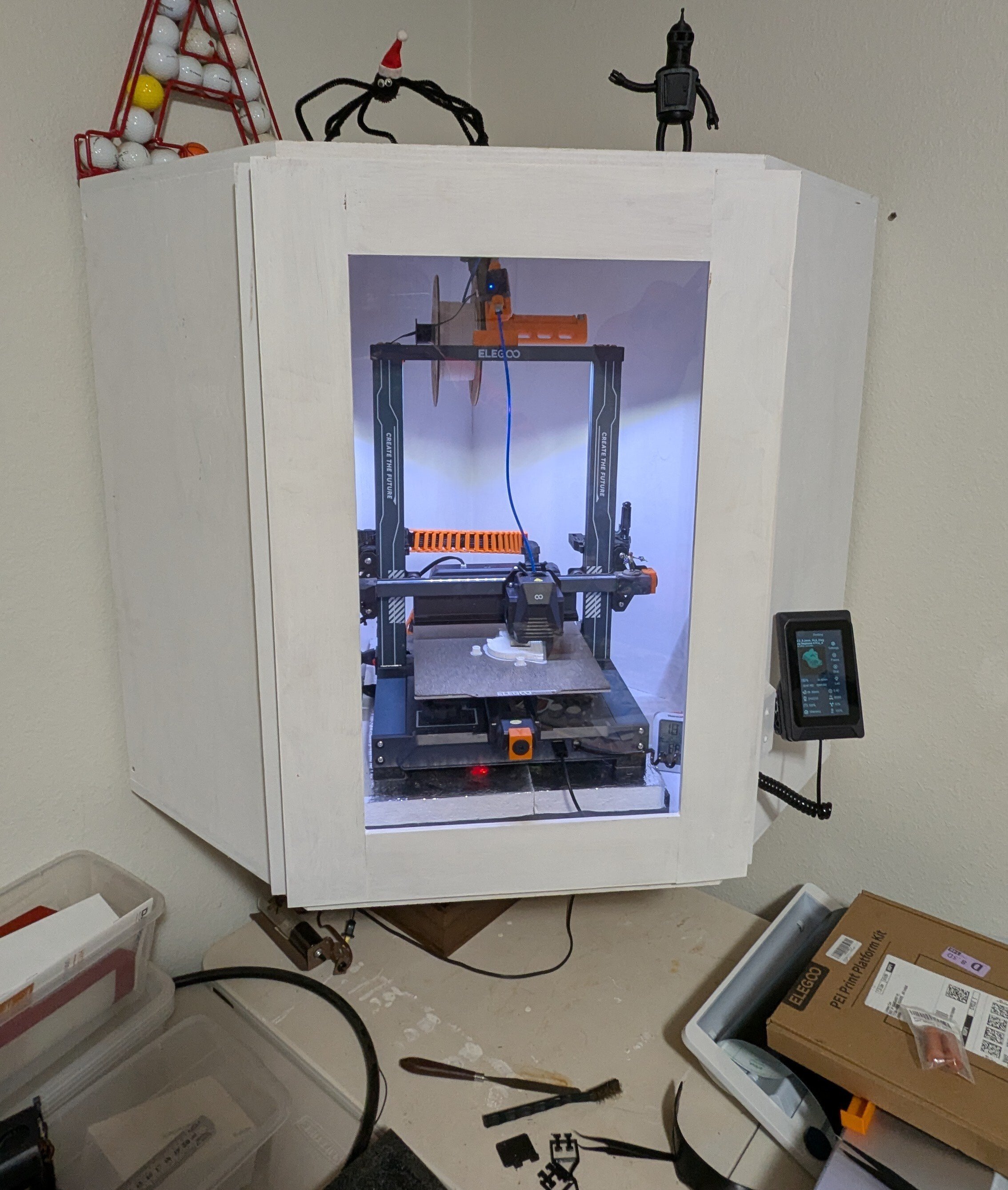

I should have built this thing from the word go. I ran this printer for almost a year on my desk right next to my computer. But it was loud and smelly and the high traffic area played havoc on print quality and caused a lot of warping.

Now that it’s tucked away in a back room suspended in a corner by French cleats and sitting directly on top of dense foam and a big ass paver it is merely “audible” but certainly ignorable. There’s also no more headaches from the smell, and my print quality has never been better.

Do yourself and your printer a favor and get an enclosure sorted out asap.

Nailed it! I had every intention of screwing the carcass directly to the cleat but the enclosure made of one and a half sheets of 3/4 ply so it was very heavy and didn’t budge even before I added the paver and the printer so I just never ended up doing it. 🤷♂️