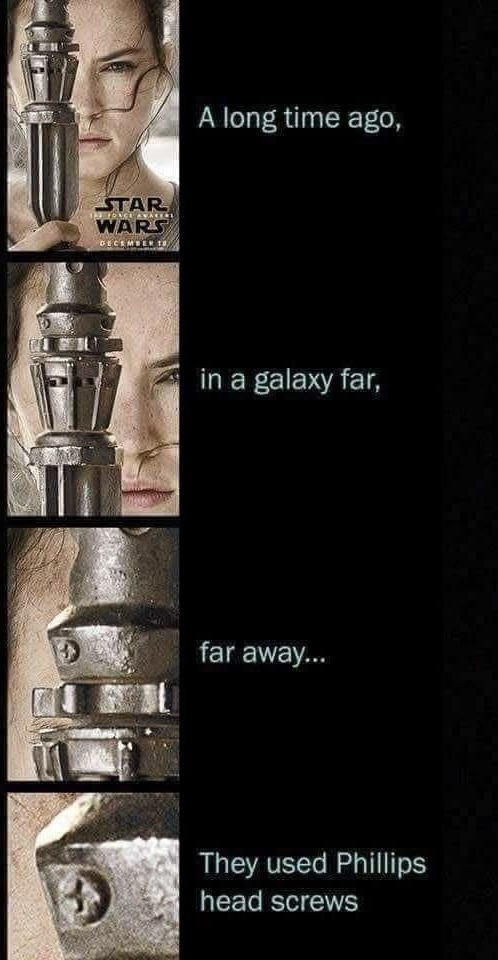

Turns out the laws of physics and geometry are the same everywhere.

Then why would they end up with philips instead of torx?

They get sick pleasure from inflicting stupid fastener design on their users?

Even in fictional universes that have wizards in space with swords made of light?

Yes!

Thought it was gonna be the Phillip’s head strip

Its all fun and games until the Canadians show up.

As an American, we made a mistake in not adopting those. Torx or whatever isn’t even as good.

Torx is better than whatever this Canadian abomination is. You’d only put pressure on the corners in a realistic setting. These would get rounded so fast unless they are massive, like on some differentials or gearbox oil drains.

This guy mechanics

Indeed torx is so good because it attempts to maximize the surface where pressure is applied to. This is good on smaller sized bolts that are more prone to being rounded, but especially amazing when removing bolts that may have been exposed and potentially corroded

Hex was for that before.

Yeah, hex is very nice but torx is improvement over it.

I have not checked on it, but I’m like 97.25% sure wood screws jumped from Philips to torx however because of corrosion resistance. Hex is very easy to round already as is on smaller sizes, but even more so if the head is exposed to elements and corroded. Of course material matters a lot, but even stainless corrodes over time.

Torx has to be very, very bad condition for it to round, it’s more likely for the screw to snap

Sorry for drunk rambling but I really like bolts. And bearings for what it’s worth

Curious how “really like bolts. And bearings!” is working out on your Tindr profile?

Luckily I’ve never had a tinder profile. And my wife liked my nuts so we’re good

Never had or seen a stripped Robertson, they are robust AF. Don’t ask me the physics. (They go deep into the screw head because of the simple shape, maybe that has part of it. And they are tapered, it’s not just a square, so they manage to grip the bit like a mofo. You don’t cam out of a Robertson.)

I’ve snapped so many Robertson bits in my life. Screws are fine.

1 5/8" cement board screws

They used to be Robertson. They switched to Torx.

Night and day difference

Like you said, they do grip like a mofo, and with an impact driver, the bits snap.

I tried dozens of different brands of bits. Even paid top dollar for special Milwaukee ones.

I was at a point where I had to pre-drill and counter sink the screws because I was breaking too many bits.

I could probably drive a torx head one through a board

Hex already fit that niche.

Torx was just so they could make wood screws that weren’t Robertson and it bled out from there.

Torx bits are waaaay stronger than hex. Like double the surface area and tapered to work when corroded.

My 30 year old VW axles with hex bolts were a nightmare. The new ones are all Torx or 12pt.

I ended to driving an oversized Torx but into the nearly stripped hex bolts to finally remove them.

Oh okay. So just like with everything else we’ve failed to do

Germany has entered the chat.

I’ve stripped more internal hex than all other types combined

The internal hex on sway bar end links are useless after any time in the salt. Last time I had to remove them I went straight to the angle grinder and ordered a new pair. Didn’t even attempt it.

We have to go deeper.

Yeah boi

Hey, if it works it works.

It works, but badly. All my homies hate cam-out and love torx.

It works great for it’s intended purpose which is torque limiting.

Correct. The original patent makes no reference to any sort of cam out / torque limiting feature.

Well, limiting torque but killing itself and becoming extremely hard to remove is terrible design lol

Even in a galaxy far far away everything is still made in china

Edit: at least they didn’t use Phillips screws

Can’t get more spacey screws than those. They basically look like galaxies

That’s because they were worried someone would have taken them off.

Disappointed that the first comment isn’t, “May the Torx be with you”

That may have been the actual post title I was looking for.

These aren’t the post titles you’re looking for… 👋

I changed it after the fact but I went with torque instead of Torx because it seemed to make more sense. IYKYK.

Nah, I was just kiddin’!

This was a great post and fun to comment with

Thanks. Most of my memes are stolen but as long as I manage to bring a smile to a few faces each day, it’s worth it.

Ironically enough other standards appeared because of the need of more torque.

That’s the joke

Um, actually, those are rigid kal’dron adjustment pins used to correct focus crystal orientation.

Can we all agree that flathead should be outlawed and Phillips needs to get phased out with a quickness

Why are there so many fasteners 8min : https://youtu.be/5cA9bZRHpZE

Officially, “flathead” refers to countersunk screws. Slotted screws are terrible for my purposes, but they actually do have 1 advantage. If they get mud or something caked up in the slot it’s relatively easy to use a knife or some other pointy thing to clean it out. Guns and other things used in dirty environments often use slotted fasteners for that reason.

Yeah it also really difficult to strip a Flathead slot.

But it can be done! https://media.tenor.com/3dnzk_8PqwoAAAAM/dumb-and-dumber-jim-carrey.gif

Right, field maintenance, especially when you don’t have access to tools is a bit of an exception. Personally I think using take down pins for guns is the way to go for field maintenance anyway.

I don’t get the problem with flathead, for household applications it seems the most superior because I can use literally anything in my house to drive the screw (butter knife, credit card, a housekey)

plus almost every size of flathead screwdriver can fit in almost every size of flathead screw.

No offense, but you haven’t unscrewed/screwed enough slot screws if you don’t see why they’re worse in every way. The criteria for a good screw isn’t that you don’t have to have the correct tool. The bits are $0.99!

I unscrew a single screw and whether it’s a light switch or an electronic device, I’m already annoyed. Even if you use a flathead screwdriver that fits perfectly, it will un-center and slip out, whether you use a hand bit/screw driver or a drill.

You can use everything, but everything works badly. Even a fitting screwdriver will just randomly jump out after half a turn and scratch whatever you’re working on.

Wait what should the standard be?

Torx.

Googles it.

Omg, it has 6 sides, that means it’s bestagon

You know! ❤️

I don’t think I had ever actually seen a torx screw head until this conversation lol

If you have an iPhone, you can see two tiny torx screws on the bottom by the lightning/USB-C port

Seems to be common on furniture that you’re supposed to assemble and rearrange, such as convertible crib/beds. One of my kids’ cribs was brand new and the other we got at a garage sale and would be from 2003 or so, and both use torx for this reason

Torx for anything that needs to be torqued or used with power tools, Robertson (square) for anything intended to be used with hand tools or more finer work (a screwdriver)

Square (Robertson) and/or torx depending on application. Square should be for everyday things and torx should be for anything mechanical, yes I know there is a big gray area in the middle there, but flat head, phillips, and hex need to go.

Honest question, why not torx across the board? What do square do well that’s not covered by torx?

Robertson is tapered, so you just have to hit the hole somewhat and it’ll guide itself in real easy. Torx is fickle to line up and orientate.

The way I see it, anything with a square bit can be done by with a hand held screw driver, and anything with a torx bit should probably be torqued to a certain amount and/or be used with a screw gun. Square/Robertson bits are used super often in things like electrical panels and electronics. They are becoming pretty common for cabinetry also. I doubt you’ll see a torx screw in cabinets.

Thank you for replying. Robertson screws are not common in Scandinavia - at least I’ve never seen one IRL. I use torx for everything, never had an issue with hand screwing them, which is why I asked. But I’m not an expert or professional, just a home owner that tries to DIY as much as I can.

Not having to deal with stripped screws is the biggest plus for me, I hate having to remove a Philips or flathead screw that someone else put in some hard-to-reach location that can’t be turned without breaking. (Which happens surprisingly often, actually.)

Lol absolutely, stripped screws are the worst

I think it’s slightly more expensive to machine?

Amen, brother!

I’d say cross/slit in tiny, torx in small to big screws.

I have never in my life seen such a screw. Hexagon is the shit here, when it isnt Phillips. Maybe coming from Ikea, I don’t know. Is this format a (popular) US thing?

Ya Ikea standardized on hex because it’s cheap to mass produce. It definitely strips though.

Torx has slowly been gaining popularity in the US for a decade or two now, but sadly Phillips is still pretty popular and hex is pretty common also, you will see the square/Robertson screws a lot in electrical panels and in cabinetry but not super common at the hardware store.

Somehow, Phillips head survived.

Obligatory Babylon 5 Swedish meatballs

It is a curious fact, and one to which no one knows quite how much importance to attach, that something like 85% of all known worlds in the Galaxy, be they primitive or highly advanced, have invented a drink called jynnan tonnyx, or gee-N’N-T’N-ix, or jinond-o-nicks, or any one of a thousand or more variations on the same phonetic theme. The drinks themselves are not the same, and vary between the Sivolvian ‘chinanto/mnigs’ which is ordinary water served at slightly above room temperature, and the Gagrakackan ‘tzjin-anthony-ks’ which kill cows at a hundred paces; and in fact the one common factor between all of them, beyond the fact that the names sound the same, is that they were all invented and named before the worlds concerned made contact with any other worlds. What can be made of this fact? It exists in total isolation. As far as any theory of structural linguistics is concerned it is right off the graph, and yet it persists. Old structural linguists get very angry when young structural linguists go on about it. Young structural linguists get deeply excited about it and stay up late at night convinced that they are very close to something of profound importance, and end up becoming old structural linguists before their time, getting very angry with the young ones. Structural linguistics is a bitterly divided and unhappy discipline, and a large number of its practitioners spend too many nights drowning their problems in Ouisghian Zodahs.

That reads like it’s straight out of one of the Hitchhikers books

Preventing cam-out with a Phillips screw is like learning the ways of the Force. It takes patience and skill, something the Empire’s rigid Torx would never understand.

Huh always thought that was a self sealing stem bolt

Wrong universe

See that whooshing over your head its the Clear Air Turbulence.

No wonder the Jedi failed.

Oh man, this is 100% real. Disney is such garbage…

Meh, it’s one of those things that’s going to be around forever. I would be absolutely unsurprised if crosshead screws were still a thing in 4800 ce.

You’re building a light saber.

Do you:

A. Weld everything

Or

B. Drill holes and thread the holes for a bolt

I’m sure they have some kind of crazy riveting technology. Is she installing screws because she wants to be able to easily take apart her lightsaber if needed?

Well, the option with screws makes it more repairable.

I mean, supposedly some lightsabers were built in a cave. They probably used whatever was on hand, and I’m thinking screws are more common in rubbish strewn pits and rankor caves than welding machines.

Screws maybe

But you have to machine a hole in the metal for the screw to function

You know how hard it would be to drill a hole for a screw in a cave with scrap parts and no power drill?

All you need to crudely weld, probably as strong as a screw, is heat. Fire is easy in a cave.

I’d wager they could melt some metal together before devising a cave drill press.

We have no idea what metal or alloy it is. They could have an alloy that melts easily, but once hard, it adheres to other metals and practically unbreakable. Just find some scraps of that alloy to easily weld.

Republic era lightsabers used neither. They held themselves together kinda like jointing in woodwork.

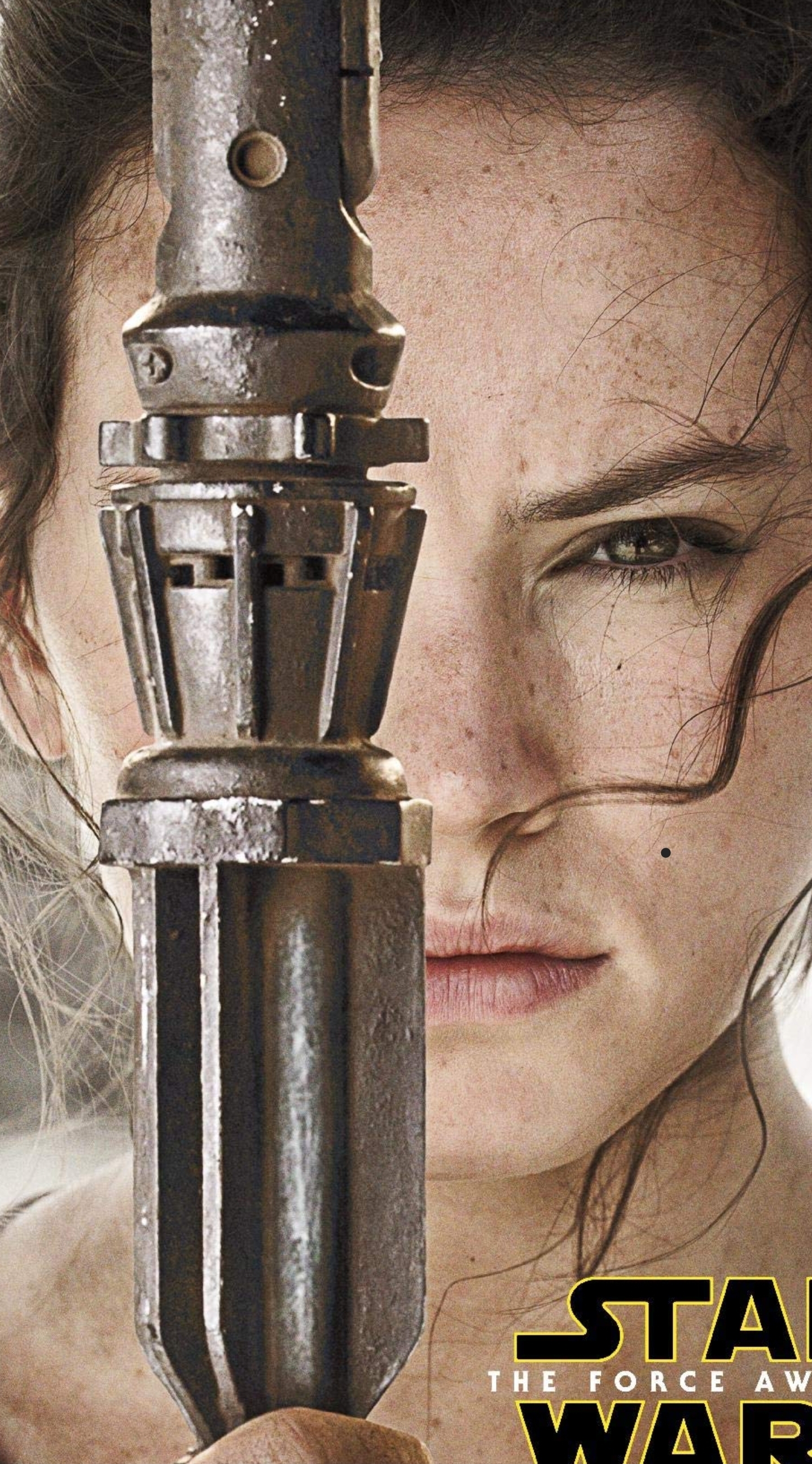

Also the image doesn’t show a lightsaber? It’s a bo-staff built out of literal scraps?

That depends, is the person building it a DIY tinker, or a mass production factory worker? Because a tinkerer is absolutely going to want to open it up easily.

deleted by creator

Or perhaps the Jedi are also just cooking with water.