The other ones:

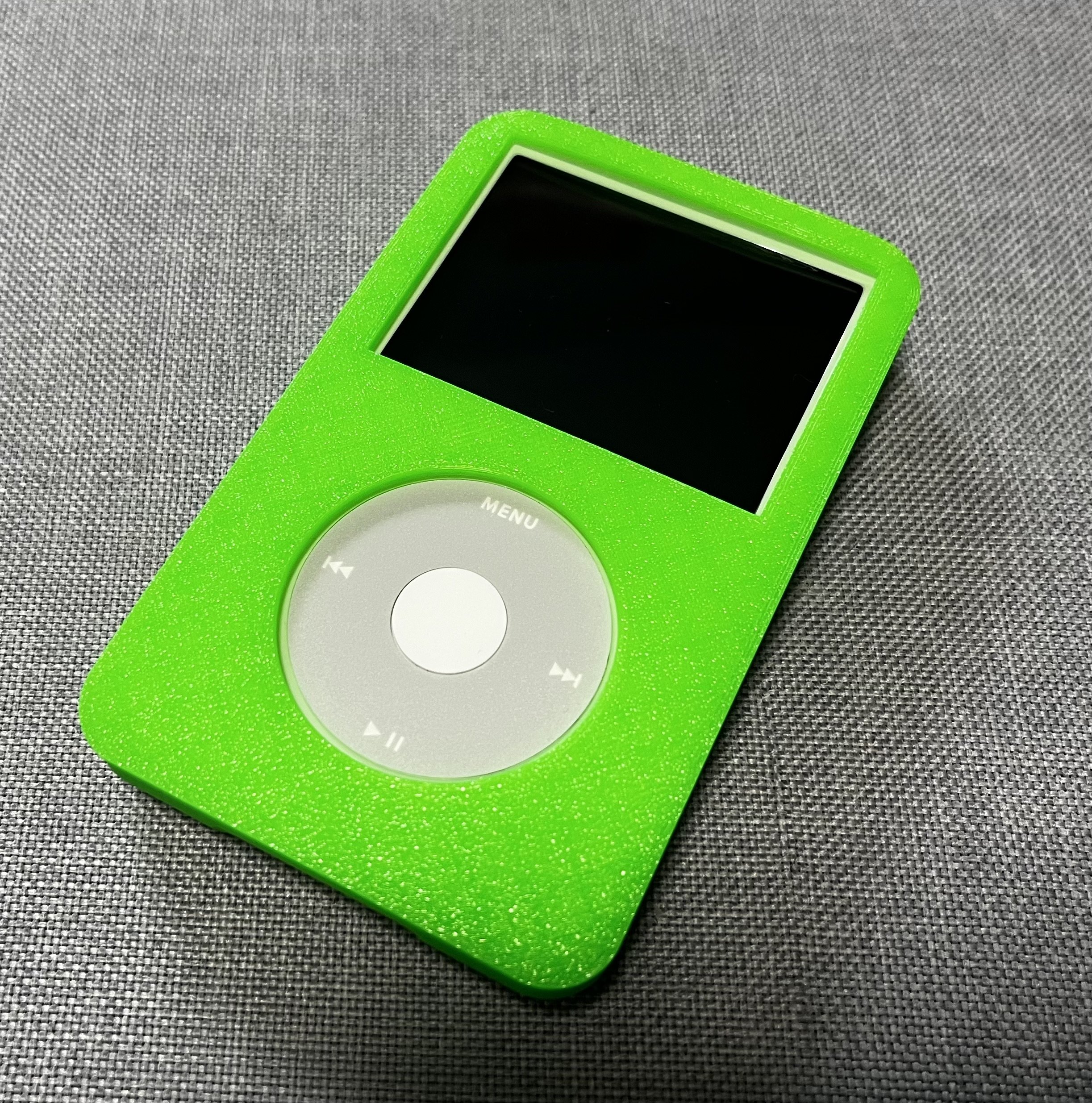

And today evening I will print a case for my recently upgraded trusty old iPod:

Update:

After a few changes the second prototype came out great, files also available for free now on my printables:

If interested, you can find most of the designs above on my Printables profile for free:

Amazing work man! 👍

Thank you!

I read Pinterest instead of Printables at first and got ready to shit bricks and throw tables. What am I gonna do with all these bricks and tables!?

That honeycomb design is sick, almost makes me wish I had an iPhone :D

What phone do you have?

Xiaomi Poco X3 NFC. Doubt there’s enough people running around with this this that it’s worth putting time into making a case for it :D

Will this one fit your phone? If yes, I can modify it for you how you like ;)

That sure looks like it fits! If I may make a request then, I’d love that with the full honeycomb back like that yellow case.

Please and thank you, and let me know if I can send you a fiver somehow :)

Here you are:

https://www.printables.com/de/model/553039-xiaomi-pocophone-x3-case

Let me know if it fits. Would love to see a picture :)

Better donate the money to a charitable cause. I’m doing this just for fun.

You rock, thanks a bunch! :)

My pleasure! I just added a second version with the lanyard holes ;)

This is how it starts. Next thing you’ll know you’ll be optimizing phone shapes, learning physics about drop protections, and soon starting your own case company.

You might be right, I looked up a lot how Spigen gets their cases durable recently in order to create a really rugged version :D

Word of warning, 3d printed cases are a bad idea. The plastics don’t actually absorb the impact like a real case would, and so they break often and don’t actually absorb the impact and protect your phone. Every time I’ve used one I’ve ended up with damage.

Did you use TPU for the prints? If you used PLA, that really was a bad idea. With TPU my drop tests (not on purpose) were successful and the phone without damage everytime (so far)

I used nylon carbon fiber.

That sounds durable, but not flexible. Am I right?

It’s durable, and is not inflexible but is quite brittle. I have also tried in pla and got similar results. It just never ended well.

I get your problem, yes. I also tried printing a bumper for my work phone in PLA a couple times before I was able to print TPU and it always took like 2 weeks until it broke. Those materials don’t like being put under pressure permanently. I didn’t try PETG, could imagine it to be a little better, even though it won’t absorb any impact if dropped.

It depends how thick and soft the tpu is. If you have a thick enough and soft enough case, it will absorb an impact. Just like silicone cases do. And they are also solid.

Those look super nifty. It makes me wish I had a printer.

Thank you!

Most libraries have a printer you can use.

Thank you for the suggestion. Do you just reserve it for the hours it takes to print? It was my understanding that these take a long time to print.

Depends on the library, but typically it’s first come first served. You give them the file and they print it, and you pay for the filament used.

They take from 5.5 to 11 hours to print (depending on the version you choose). Printed these with 0.2 layer height, 15% Infill and supports while laying on the back.

BTW… In the process of designing these there were made a few prototypes. They all are not perfect, but if someone (from Germany) wants one, here is my stock :D If you have questions on a specific one just ask. I would give them away for shipping+packaging cost.

iPhone 13 (regular):

- blue Mama Version

- big MagSafe Cutout Bumper

iPhone 13 Mini:

- slim hex back yellow

- thicker round hex cutout transparent

- rugged small hex back yellow with grip pattern

iPod Classic 5G:

- neon green case with hex back

How soft/bendable is it compared to silicon cases?

It’s flexible enough to get a phone into it, but it still feels pretty stiff, depending on thickness and infill settings. It’s flexible but not really stretchy.

As long as it’s flexible enough, it’s probably enough to protect the phone when falling on a hard surface. Just another reason to get a 3d printer. I’m having a hard time finding cases that I want and never thought it’s possible to make one using 3d printer.

I threw mine a couple times now with the new case, so far it’s doing a great job (using the neon green one with the blue lanyard for myself). But it highly depends on the type of case you print or to be more precise on thickness and buildtype. If it’s thick enough and protects all the edges, you probably will be as save as with a usual case you would buy (at least that’s what I feel right now after I designed and printed these). But if you print one, that’s very thin, then your phone might get damaged when dropped.

You’re absolutely right. I had the same problem. Always wanted the case I am using right now, but I just wasn’t able to find one. Feels like a bit more freedom right now. And for the price of one good case from Amazon I now print multiple. But yes, I paid for the printer, material and electricity. If my calculations are right, my printer paid off already after I printed a holder for my wife’s hairdryer. If I would have bought one, it would have cost me about 130€, absolutely insane. My printer with all upgrades cost me 300€ by now btw. So definitely get yourself one :)

Maybe this helps:

Ah that’s way better than I expected!

I’ve had pretty good results with TPU as well. However I recently found some filament called soft PLA which has been similar structural properties to TPU, but seems a little more forgiving with print settings.

Interesting, could you share a link please?

Here’s the stuff I used.

Thanks!

This is amazing! Well, great excuse to buy more TPU :)

Oh you are so right :D I bought 3 rolls last week… Using this one for my cases btw:

SUNLU TPU Filament, 1KG Flexibles 95A TPU 3D Drucker Filament 1.75mm Maßgenauigkeit +/- 0.03 mm, Hohe Liquidität und Elastizität, 1KG(2.2Lbs) Spule, TPU Filament für FDM 3D Drucker,TPU Gelb https://amzn.eu/d/872AVs6

Thanks for the tip!

How well does the Lego one work with actual Lego bricks?

Perfect! I used the actual Lego dimensions. Made that one for a friend who owns a Lego store

Edit:

Didn’t upload that one yet. But I can if someone wants it ;)

Edit: spelling

Enjoying the paracord, I might give this a go on my current case. How does the connection look like?

I tried to make it easy to print, here are some more detailed pictures:

Damn, I was hoping that was a jump rope.

No, a jump robe would be a bit too thick I think. But you can get cheap „Paracord“ on AliExpress, Whish or Temu. Pretty sure on eBay and Amazon too (even though a bit more expensive).

How much more difficult is it to print TPU compared to PLA?

I would say that depends on you, your printer and the used filament.

On my Voxelab Aquila out of the box with official slicing Software I could print PLA without issues, but with TPU it would have been impossible. Now I use Astroprint.com for slicing where I control print settings in more detail than it would be possible with Voxelab’s slicer. So that was the first step to take. Also I upgraded my printer to DirectDrive and DualGearExtruder. I then needed a new fan shroud, because the one I used before didn’t fit anymore. Then I had to learn about e-steps, because somehow I went into Unterextrusion (after switching to the dualgear Extruder you need to get the e-steps set new depending on the new extrudergear thickness. Luckily it was mentioned on the package it came in). Then the TPU started wrapping around the extruder gears. Turns out I printed too fast and so on…

Long story short. Depending on your printer, I would suggest at least switching to DirectDrive if your printer doesn’t have it. Also print very slowly, like 20mm/s slowly.

Have you tried printing with infill but no top or bottom layer? You can get a pretty nice look with stuff like exposed gyroid infill.

I did this for a few inserts for like glasses holders and stuff, but not yet for smartphone cases. Wouldn’t it then also expose the top of the edges? Also I think it would probably collect very fast, very much dirt in my pockets :D

It depends how thick the top edge is. You can also enable ironing to smooth out the top and make it less visible.

I don’t think it’s much worse than your examples with holes in them.

Hmm… the top edge is round, so it might work. Maybe I will give that I try :)

The dirt gets trough the hex-holes to the phone, yes. But I believe in the gyroid infill it will get stuck somewhere in between and then not be easy to clean (depending on the type of dirt :D)

I haven’t had that issue, but maybe I just have really clean pockets.

If the case isn’t too thick, you don’t get the full infill and you get fewer pockets for any dirt to get caught as well. You can adjust the % of infill to get the pattern size/depth you want as well.

Maybe, yes :D I think maybe I can somehow get only the back part to be printed without top and bottom, would definitely look more professional. I need to play around a bit with my slicer.

What modelling software are u using?

I am using fusion360

ah this is the professional CAD tool from autodesk. I only used the minimalistic web version of Tinker CAD, probaly enough to do small customizations on cases

Yes, I use the free version. I tried TinkerCAD, but actually I find it more difficult than fusion :D But I highly recommend getting a 360 CAD mouse for better use.

What orientation do you print these in? Looks like you’d need supports and I’ve had trouble getting nice finishes on the side that needs the supports. I’ve only printed with PLA though.

I printed most of them laying on the back to get this nice PEI printbed finish. The only one I printed upside down is the LEGO one, because I was afraid the back would look ugly if supports where on it. Of course you could print all of them facing the back up, so the „ugly“ supported sides are inside. You obviously will need more filament that way because of the supports, but it should work just fine.

BUT…

I highly recommend printing these in TPU, not PLA. I don’t know if you will even be able to get your phone in these, as they get a bit around the phone and PLA is not really flexible. And even if you get it in, it will possibly brake fast and not protect your phone they way it should.

Edit:

Here is how it looks after slicing. The brighter parts are supports.

Oh of course I’d print them in TPU. I was just saying that because I have no experience with printing it and if the ugly side is as ugly with TPU. That’s my only concern with printing a phone case. I’m pretty new to 3d printing so I only just learned some the limitations and the ugly side of things lol.

Ah okay, then I got you wrong. I edited my last comment with a picture that shows the supports, so you get an idea where the „ugly“ parts would occur. I made good experiences with gas lighters (not normal ones, the ones which flames look a bit like a blowtorch). With these you can carefully warm the TPU and try to make the ugly parts a little more beautiful. You can as well use a clean soldering iron to iron the ugly parts a bit more flat.

I see that. Doesn’t look too bad. Appreciate the picture. I’ll have to do some experimenting trying what you’ve suggested.

Feel free to ask if you need further help ;)